Language :

Select your language

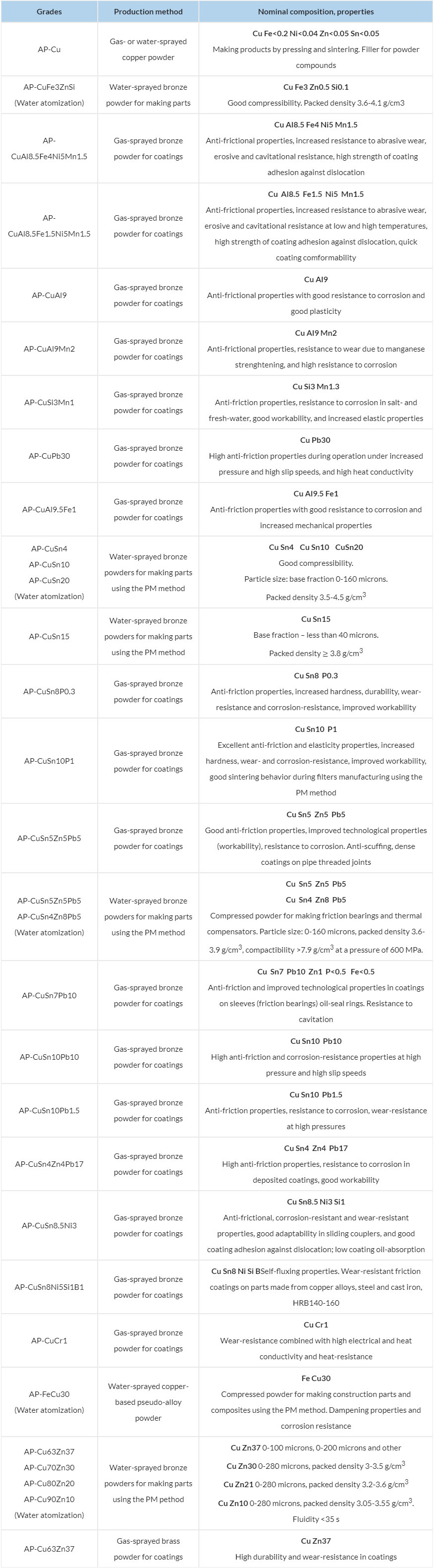

Grades, production method, chemical composition and properties

| Grades | Production method | Nominal composition, properties |

|---|---|---|

| AP-Cu | Gas- or water-sprayed copper powder |

Cu Fe<0.2 Ni<0.04 Zn<0.05 Sn<0.05 Making products by pressing and sintering. Filler for powder compounds |

| AP-CuFe3ZnSi (Water atomization) |

Water-sprayed bronze powder for making parts |

Cu Fe3 Zn0.5 Si0.1 Good compressibility. Packed density 3.6-4.1 g/cm3 |

| AP-CuAl8.5Fe4Ni5Mn1.5 | Gas-sprayed bronze powder for coatings |

Cu Al8.5 Fe4 Ni5 Mn1.5 Anti-frictional properties, increased resistance to abrasive wear, erosive and cavitational resistance, high strength of coating adhesion against dislocation |

| AP-CuAl8.5Fe1.5Ni5Mn1.5 | Gas-sprayed bronze powder for coatings |

Cu Al8.5 Fe1.5 Ni5 Mn1.5 Anti-frictional properties, increased resistance to abrasive wear, erosive and cavitational resistance at low and high temperatures, high strength of coating adhesion against dislocation, quick coating comformability |

| AP-CuAl9 | Gas-sprayed bronze powder for coatings |

Cu Al9 Anti-frictional properties with good resistance to corrosion and good plasticity |

| AP-CuAl9Mn2 | Gas-sprayed bronze powder for coatings |

Cu Al9 Mn2 Anti-frictional properties, resistance to wear due to manganese strenghtening, and high resistance to corrosion |

| AP-CuSi3Mn1 | Gas-sprayed bronze powder for coatings |

Cu Si3 Mn1.3 Anti-friction properties, resistance to corrosion in salt- and fresh-water, good workability, and increased elastic properties |

| AP-CuPb30 | Gas-sprayed bronze powder for coatings |

Cu Pb30 High anti-friction properties during operation under increased pressure and high slip speeds, and high heat conductivity |

| AP-CuAl9.5Fe1 | Gas-sprayed bronze powder for coatings |

Cu Al9.5 Fe1 Anti-friction properties with good resistance to corrosion and increased mechanical properties |

| AP-CuSn4 AP-CuSn10 AP-CuSn20 (Water atomization) |

Water-sprayed bronze powders for making parts using the PM method |

Cu Sn4 Cu Sn10 CuSn20 Good compressibility. Particle size: base fraction 0-160 microns. Packed density 3.5-4.5 g/cm3 |

| AP-CuSn15 | Water-sprayed bronze powders for making parts using the PM method |

Cu Sn15 Base fraction – less than 40 microns. Packed density ≥ 3.8 g/cm3 |

| AP-CuSn8P0.3 | Gas-sprayed bronze powder for coatings |

Cu Sn8 P0.3 Anti-friction properties, increased hardness, durability, wear-resistance and corrosion-resistance, improved workability |

| AP-CuSn10P1 | Gas-sprayed bronze powder for coatings |

Cu Sn10 P1 Excellent anti-friction and elasticity properties, increased hardness, wear- and corrosion-resistance, improved workability, good sintering behavior during filters manufacturing using the PM method |

| AP-CuSn5Zn5Pb5 | Gas-sprayed bronze powder for coatings |

Cu Sn5 Zn5 Pb5 Good anti-friction properties, improved technological properties (workability), resistance to corrosion. Anti-scuffing, dense coatings on pipe threaded joints |

| AP-CuSn5Zn5Pb5 AP-CuSn4Zn8Pb5 (Water atomization) |

Water-sprayed bronze powders for making parts using the PM method |

Cu Sn5 Zn5 Pb5 Cu Sn4 Zn8 Pb5 Compressed powder for making friction bearings and thermal compensators. Particle size: 0-160 microns, packed density 3.6-3.9 g/cm3, compactibility >7.9 g/cm3 at a pressure of 600 MPa. |

| AP-CuSn7Pb10 | Gas-sprayed bronze powder for coatings |

Cu Sn7 Pb10 Zn1 P<0.5 Fe<0.5 Anti-friction and improved technological properties in coatings on sleeves (friction bearings) oil-seal rings. Resistance to cavitation |

| AP-CuSn10Pb10 | Gas-sprayed bronze powder for coatings |

Cu Sn10 Pb10 High anti-friction and corrosion-resistance properties at high pressure and high slip speeds |

| AP-CuSn10Pb1.5 | Gas-sprayed bronze powder for coatings |

Cu Sn10 Pb1.5 Anti-friction properties, resistance to corrosion, wear-resistance at high pressures |

| AP-CuSn4Zn4Pb17 | Gas-sprayed bronze powder for coatings |

Cu Sn4 Zn4 Pb17 High anti-friction properties, resistance to corrosion in deposited coatings, good workability |

| AP-CuSn8.5Ni3 | Gas-sprayed bronze powder for coatings |

Cu Sn8.5 Ni3 Si1 Anti-frictional, corrosion-resistant and wear-resistant properties, good adaptability in sliding couplers, and good coating adhesion against dislocation; low coating oil-absorption |

| AP-CuSn8Ni5Si1B1 | Gas-sprayed bronze powder for coatings | Cu Sn8 Ni Si BSelf-fluxing properties. Wear-resistant friction coatings on parts made from copper alloys, steel and cast iron, HRB140-160 |

| AP-CuCr1 | Gas-sprayed bronze powder for coatings |

Cu Cr1 Wear-resistance combined with high electrical and heat conductivity and heat-resistance |

| AP-FeCu30 (Water atomization) |

Water-sprayed copper-based pseudo-alloy powder |

Fe Cu30 Compressed powder for making construction parts and composites using the PM method. Dampening properties and corrosion resistance |

| AP-Cu63Zn37 AP-Cu70Zn30 AP-Cu80Zn20 AP-Cu90Zn10 (Water atomization) |

Water-sprayed bronze powders for making parts using the PM pethod |

Cu Zn37 0-100 microns, 0-200 microns and other Cu Zn30 0-280 microns, packed density 3-3.5 g/cm3 Cu Zn21 0-280 microns, packed density 3.2-3.6 g/cm3 Cu Zn10 0-280 microns, packed density 3.05-3.55 g/cm3. Fluidity <35 s |

| AP-Cu63Zn37 | Gas-sprayed brass powder for coatings |

Cu Zn37 High durability and wear-resistance in coatings |