Language :

Select your language

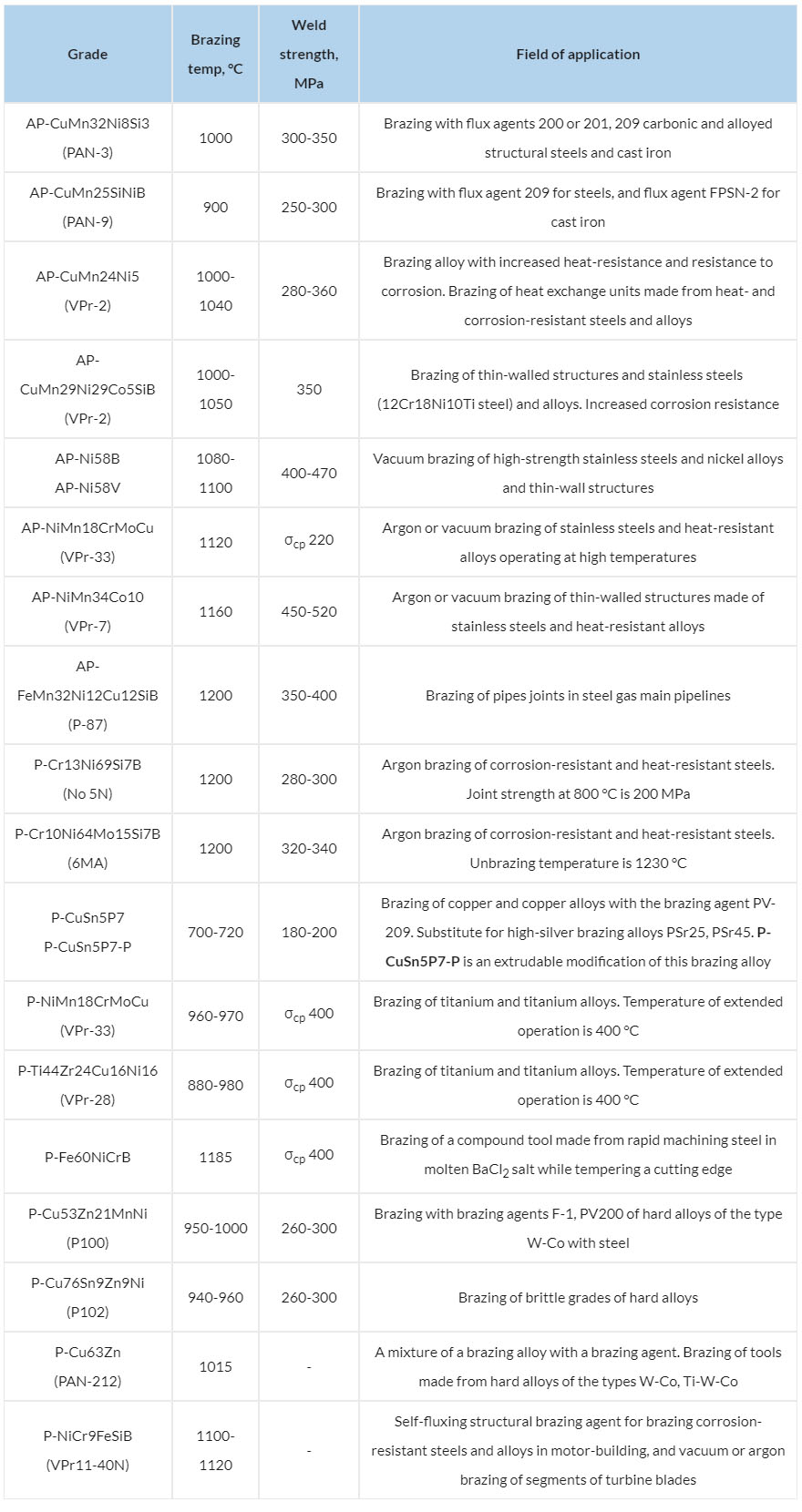

| Grade | Brazing temp, °C | Weld strength, MPa | Field of application |

|---|---|---|---|

| AP-CuMn32Ni8Si3 (PAN-3) |

1000 | 300-350 | Brazing with flux agents 200 or 201, 209 carbonic and alloyed structural steels and cast iron |

| AP-CuMn25SiNiB (PAN-9) |

900 | 250-300 | Brazing with flux agent 209 for steels, and flux agent FPSN-2 for cast iron |

| AP-CuMn24Ni5 (VPr-2) |

1000-1040 | 280-360 | Brazing alloy with increased heat-resistance and resistance to corrosion. Brazing of heat exchange units made from heat- and corrosion-resistant steels and alloys |

| AP-CuMn29Ni29Co5SiB (VPr-2) |

1000-1050 | 350 | Brazing of thin-walled structures and stainless steels (12Cr18Ni10Ti steel) and alloys. Increased corrosion resistance |

| AP-Ni58B AP-Ni58V |

1080-1100 | 400-470 | Vacuum brazing of high-strength stainless steels and nickel alloys and thin-wall structures |

| AP-NiMn18CrMoCu (VPr-33) |

1120 | σcp 220 | Argon or vacuum brazing of stainless steels and heat-resistant alloys operating at high temperatures |

| AP-NiMn34Co10 (VPr-7) |

1160 | 450-520 | Argon or vacuum brazing of thin-walled structures made of stainless steels and heat-resistant alloys |

| AP-FeMn32Ni12Cu12SiB (P-87) |

1200 | 350-400 | Brazing of pipes joints in steel gas main pipelines |

| P-Cr13Ni69Si7B (No 5N) |

1200 | 280-300 | Argon brazing of corrosion-resistant and heat-resistant steels. Joint strength at 800 °C is 200 MPa |

| P-Cr10Ni64Mo15Si7B (6MA) |

1200 | 320-340 | Argon brazing of corrosion-resistant and heat-resistant steels. Unbrazing temperature is 1230 °C |

| P-CuSn5P7 P-CuSn5P7-P |

700-720 | 180-200 | Brazing of copper and copper alloys with the brazing agent PV-209. Substitute for high-silver brazing alloys PSr25, PSr45. P-CuSn5P7-P is an extrudable modification of this brazing alloy |

| P-NiMn18CrMoCu (VPr-33) |

960-970 | σcp 400 | Brazing of titanium and titanium alloys. Temperature of extended operation is 400 °C |

| P-Ti44Zr24Cu16Ni16 (VPr-28) |

880-980 | σcp 400 | Brazing of titanium and titanium alloys. Temperature of extended operation is 400 °C |

| P-Fe60NiCrB | 1185 | σcp 400 | Brazing of a compound tool made from rapid machining steel in molten BaCl2 salt while tempering a cutting edge |

| P-Cu53Zn21MnNi (P100) |

950-1000 | 260-300 | Brazing with brazing agents F-1, PV200 of hard alloys of the type W-Co with steel |

| P-Cu76Sn9Zn9Ni (P102) |

940-960 | 260-300 | Brazing of brittle grades of hard alloys |

| P-Cu63Zn (PAN-212) |

1015 | - | A mixture of a brazing alloy with a brazing agent. Brazing of tools made from hard alloys of the types W-Co, Ti-W-Co |

| P-NiCr9FeSiB (VPr11-40N) |

1100-1120 | - | Self-fluxing structural brazing agent for brazing corrosion-resistant steels and alloys in motor-building, and vacuum or argon brazing of segments of turbine blades |