Language :

Select your language

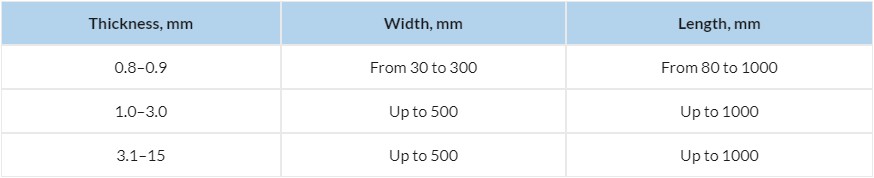

Dimensions of sheets made from MoW-PM alloy

| Thickness, mm | Width, mm | Length, mm |

|---|---|---|

| 0.8–0.9 | From 30 to 300 | From 80 to 1000 |

| 1.0–3.0 | Up to 500 | Up to 1000 |

| 3.1–15 | Up to 500 | Up to 1000 |

Sheets are delivered annealed for internal stress removal and with tested microstructure.

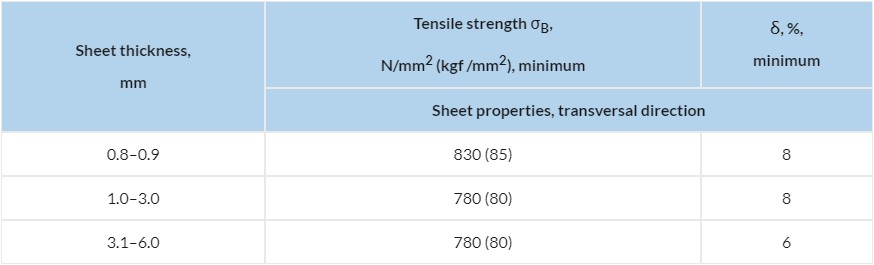

Guaranteed mechanical properties of sheets at room temperature

| Sheet thickness, mm |

Tensile strength σB, N/mm2 (kgf /mm2), minimum |

δ, %, minimum |

|---|---|---|

| Sheet properties, transversal direction | ||

| 0.8–0.9 | 830 (85) | 8 |

| 1.0–3.0 | 780 (80) | 8 |

| 3.1–6.0 | 780 (80) | 6 |

EXTRUDED STOCK FROM MoW-2-PM ALLOY

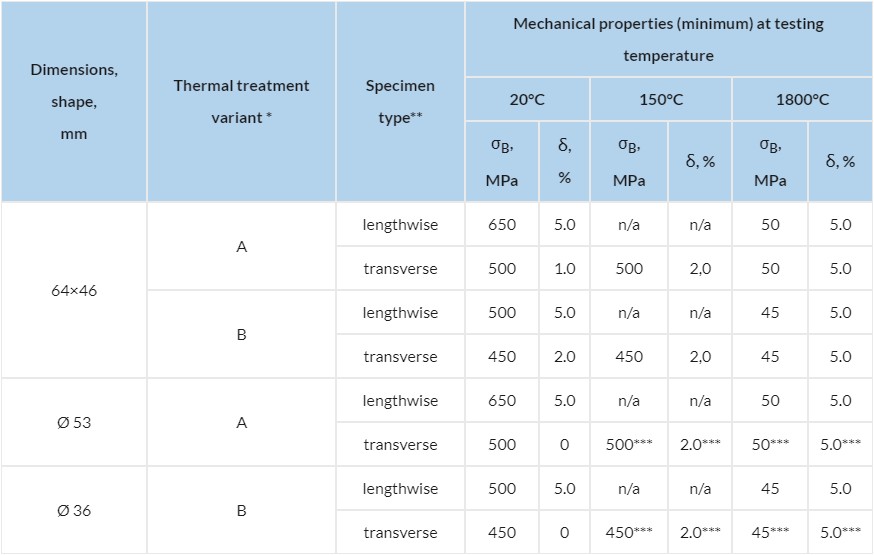

Guaranteed mechanical properties of MoW-2-PM extruded stock

| Dimensions, shape, mm |

Thermal treatment variant * | Specimen type** | Mechanical properties (minimum) at testing temperature | |||||

|---|---|---|---|---|---|---|---|---|

| 20°C | 150°C | 1800°C | ||||||

| σB, MPa | δ, % | σB, MPa | δ, % | σB, MPa | δ, % | |||

| 64×46 | A | lengthwise | 650 | 5.0 | n/a | n/a | 50 | 5.0 |

| transverse | 500 | 1.0 | 500 | 2,0 | 50 | 5.0 | ||

| B | lengthwise | 500 | 5.0 | n/a | n/a | 45 | 5.0 | |

| transverse | 450 | 2.0 | 450 | 2,0 | 45 | 5.0 | ||

| Ø 53 | A | lengthwise | 650 | 5.0 | n/a | n/a | 50 | 5.0 |

| transverse | 500 | 0 | 500*** | 2.0*** | 50*** | 5.0*** | ||

| Ø 36 | B | lengthwise | 500 | 5.0 | n/a | n/a | 45 | 5.0 |

| transverse | 450 | 0 | 450*** | 2.0*** | 45*** | 5.0*** | ||

MoW30-PM CRUCIBLES FROM MOLYBDENUM-TUNGSTEN ALLOY

Use

MoW30 molybdenum-tungsten alloy, strengthened with a solid solution of tungsten, features temperature resistance and creeping resistance that is higher than molybdenum, and higher machinability than tungsten.

MoW30-PM crucibles made from sintered and forged molybdenum-tungsten alloy are used primarily to melt corundum in technologies for growing extremely pure sapphire single crystals.

Chemical composition of crucibles

Molybdenum is the base, with 28–32% tungsten. The alloy may be additionally strengthened with admixtures of B, Hf, Y, Zr, C.

PRODUCTS MADE FROM MOLYBDENUM, TUNGSTEN AND THEIR ALLOYS FOR USE IN HIGH-TEMPERATURE FURNACES

Use

Products made from molybdenum, tungsten V-MP, and the molybdenum alloys MoW30-PM (MoW30), MoLa-PM are used to outfit vacuum and hydrogen furnaces, the heat zones of units for smelting quartz glass and growing sapphire single crystals, furnaces for the annealment of uranium fuel in the manufacture of fuel rods and for the production of components for high-temperature heat exchangers, thermoelectric converters and other devices that operate at high temperatures.

Shape and manner of production

Products are made in sintered form or from deformed (by forging or rolling) stock (sheets, plates, forced products, rods) according to the client’s drawings or according to a manner of production, geometric dimensions and tolerances for dimensions and surface roughness submitted by the client.

Products are made in simple shapes: tooled discs, slabs, rings, plates, substrata, bearing plates, rods, or electrodes; or in complex shapes: thermal screens, radiators, boats, fastening details, etc. Additional requirements regarding product specifications are set based on the client’s request.

Recommendations on use

Before use, thermal screens and other products used in a customer’s vacuum furnaces should be annealed in a vacuum of p<10–4 mmhg (torus) in the following manner:

During use, the products should not be subjected to shocks.

PRODUCTS FROM MOLYBDENUM-TUNGSTEN ALLOY MoW10-PM FOR SPUTTERING TARGETS

Use

Products made from MoW30-PM (MoW10) molybdenum-tungsten alloy are used as sputtering targets in technologies of thin films to produce electronic components and other functional coatings, as well as to produce components for high-temperature vacuum and hydrogen furnaces.

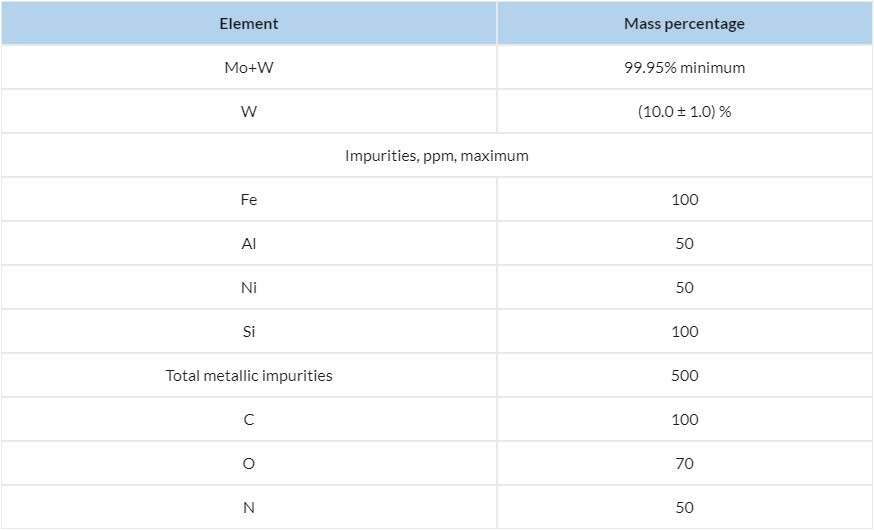

Guaranteed chemical composition of MoW10-PM 99.95% products

| Element | Mass percentage |

|---|---|

| Mo+W | 99.95% minimum |

| W | (10.0 ± 1.0) % |

| Impurities, ppm, maximum | |

| Fe | 100 |

| Al | 50 |

| Ni | 50 |

| Si | 100 |

| Total metallic impurities | 500 |

| C | 100 |

| O | 70 |

| N | 50 |

ROLLED STOCK AND PRODUCTS MADE FROM MoLa-PM LANTHANUM-TREATED MOLYBDENUM

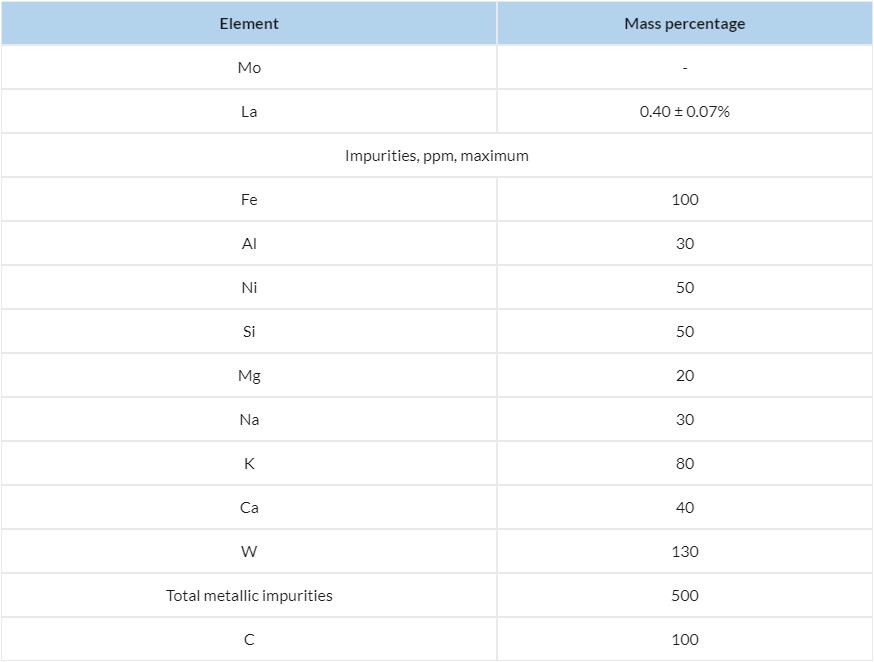

Guaranteed chemical composition of rolled stock and products made from lanthanum-treated MoLa-PM brand molybdenum

| Element | Mass percentage |

|---|---|

| Mo | - |

| La | 0.40 ± 0.07% |

| Impurities, ppm, maximum | |

| Fe | 100 |

| Al | 30 |

| Ni | 50 |

| Si | 50 |

| Mg | 20 |

| Na | 30 |

| K | 80 |

| Ca | 40 |

| W | 130 |

| Total metallic impurities | 500 |

| C | 100 |

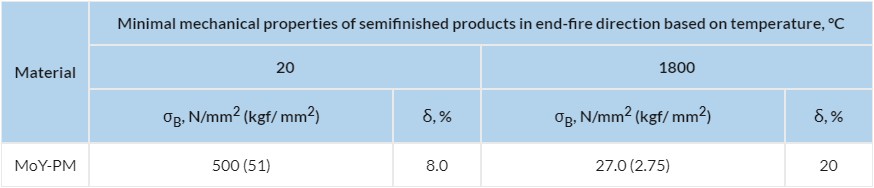

STOCK MADE FROM MoY-PM MOLYBDENUM ALLOY

Guaranteed product mechanical features

| Material | Minimal mechanical properties of semifinished products in end-fire direction based on temperature, °C | |||

|---|---|---|---|---|

| 20 | 1800 | |||

| σB, N/mm2 (kgf/ mm2) | δ, % | σB, N/mm2 (kgf/ mm2) | δ, % | |

| MoY-PM | 500 (51) | 8.0 | 27.0 (2.75) | 20 |