Language :

Select your language

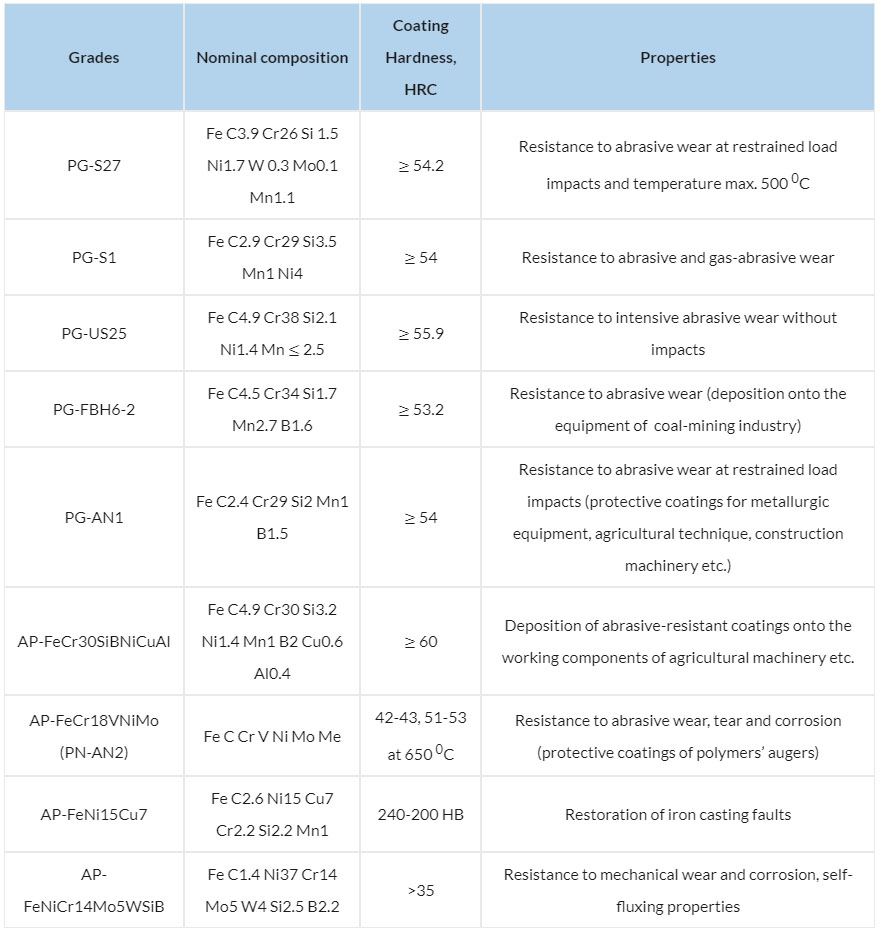

Powder grades, nominal chemical composition and properties of coatings

| Grades | Nominal composition | Coating Hardness, HRC | Properties |

|---|---|---|---|

| PG-S27 | Fe C3.9 Cr26 Si 1.5 Ni1.7 W 0.3 Mo0.1 Mn1.1 | ≥ 54.2 | Resistance to abrasive wear at restrained load impacts and temperature max. 500 0C |

| PG-S1 | Fe C2.9 Cr29 Si3.5 Mn1 Ni4 | ≥ 54 | Resistance to abrasive and gas-abrasive wear |

| PG-US25 | Fe C4.9 Cr38 Si2.1 Ni1.4 Mn ≤ 2.5 | ≥ 55.9 | Resistance to intensive abrasive wear without impacts |

| PG-FBH6-2 | Fe C4.5 Cr34 Si1.7 Mn2.7 B1.6 | ≥ 53.2 | Resistance to abrasive wear (deposition onto the equipment of coal-mining industry) |

| PG-AN1 | Fe C2.4 Cr29 Si2 Mn1 B1.5 | ≥ 54 | Resistance to abrasive wear at restrained load impacts (protective coatings for metallurgic equipment, agricultural technique, construction machinery etc.) |

| AP-FeCr30SiBNiCuAl | Fe C4.9 Cr30 Si3.2 Ni1.4 Mn1 B2 Cu0.6 Al0.4 | ≥ 60 | Deposition of abrasive-resistant coatings onto the working components of agricultural machinery etc. |

| AP-FeCr18VNiMo (PN-AN2) | Fe C Cr V Ni Mo Me | 42-43, 51-53 at 650 0C | Resistance to abrasive wear, tear and corrosion (protective coatings of polymers’ augers) |

| AP-FeNi15Cu7 | Fe C2.6 Ni15 Cu7 Cr2.2 Si2.2 Mn1 | 240-200 HB | Restoration of iron casting faults |

| AP-FeNiCr14Mo5WSiB | Fe C1.4 Ni37 Cr14 Mo5 W4 Si2.5 B2.2 | >35 | Resistance to mechanical wear and corrosion, self-fluxing properties |