Language :

Select your language

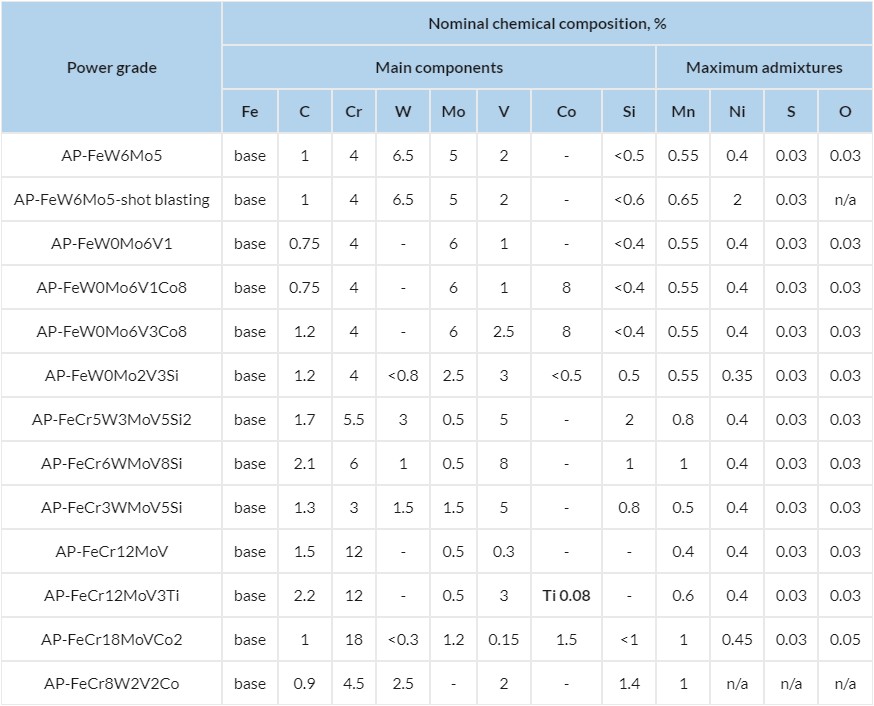

| Power grade | Nominal chemical composition, % | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Main components | Maximum admixtures | |||||||||||

| Fe | C | Cr | W | Mo | V | Co | Si | Mn | Ni | S | O | |

| AP-FeW6Mo5 | base | 1 | 4 | 6.5 | 5 | 2 | - | <0.5 | 0.55 | 0.4 | 0.03 | 0.03 |

| AP-FeW6Mo5-shot blasting | base | 1 | 4 | 6.5 | 5 | 2 | - | <0.6 | 0.65 | 2 | 0.03 | n/a |

| AP-FeW0Mo6V1 | base | 0.75 | 4 | - | 6 | 1 | - | <0.4 | 0.55 | 0.4 | 0.03 | 0.03 |

| AP-FeW0Mo6V1Co8 | base | 0.75 | 4 | - | 6 | 1 | 8 | <0.4 | 0.55 | 0.4 | 0.03 | 0.03 |

| AP-FeW0Mo6V3Co8 | base | 1.2 | 4 | - | 6 | 2.5 | 8 | <0.4 | 0.55 | 0.4 | 0.03 | 0.03 |

| AP-FeW0Mo2V3Si | base | 1.2 | 4 | <0.8 | 2.5 | 3 | <0.5 | 0.5 | 0.55 | 0.35 | 0.03 | 0.03 |

| AP-FeCr5W3MoV5Si2 | base | 1.7 | 5.5 | 3 | 0.5 | 5 | - | 2 | 0.8 | 0.4 | 0.03 | 0.03 |

| AP-FeCr6WMoV8Si | base | 2.1 | 6 | 1 | 0.5 | 8 | - | 1 | 1 | 0.4 | 0.03 | 0.03 |

| AP-FeCr3WMoV5Si | base | 1.3 | 3 | 1.5 | 1.5 | 5 | - | 0.8 | 0.5 | 0.4 | 0.03 | 0.03 |

| AP-FeCr12MoV | base | 1.5 | 12 | - | 0.5 | 0.3 | - | - | 0.4 | 0.4 | 0.03 | 0.03 |

| AP-FeCr12MoV3Ti | base | 2.2 | 12 | - | 0.5 | 3 | Ti 0.08 | - | 0.6 | 0.4 | 0.03 | 0.03 |

| AP-FeCr18MoVCo2 | base | 1 | 18 | <0.3 | 1.2 | 0.15 | 1.5 | <1 | 1 | 0.45 | 0.03 | 0.05 |

| AP-FeCr8W2V2Co | base | 0.9 | 4.5 | 2.5 | - | 2 | - | 1.4 | 1 | n/a | n/a | n/a |

AP – Atomized Powder

High Steel Powders:

AP-FeW6Mo5, AP-FeMo6V1, AP-FeMo6V1Co8, AP-FeMo6V3Co8, AP-FeMo2V3Si. AP-FeW6Mo5-b is for bead-blasting treatment, microhardness is ≥400 HV 0.05 /5 (acc. to specification); 750-1000 HV (factual).

Die Steel Powders:

AP-FeCr5W3MoV5Si2, AP-FeCr6WMoV8Si, AP-FeCr3WMoV5Si, AP-FeCr12MoV, AP-FeCr12MoV3Ti AP-FeCr18MoVCo2, AP-FeCr8W2V2Co