語言選擇:

選擇你的語言

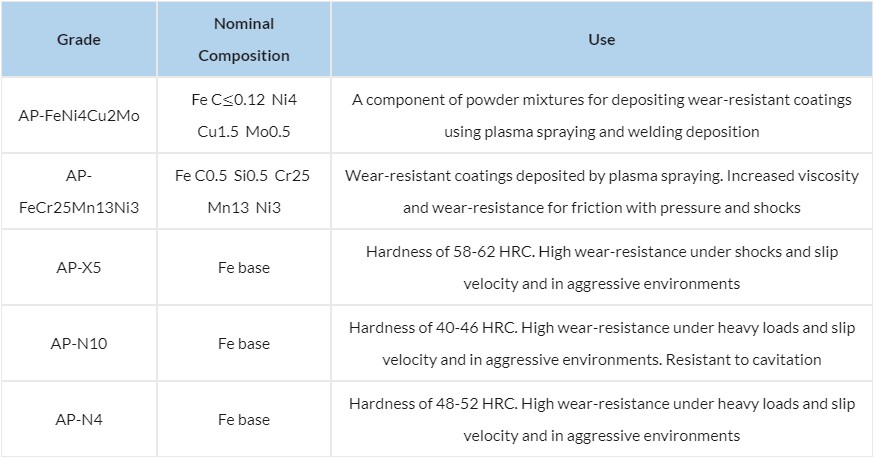

| Grade | Nominal Composition | Use |

|---|---|---|

| AP-FeNi4Cu2Mo | Fe C≤0.12 Ni4 Cu1.5 Mo0.5 | A component of powder mixtures for depositing wear-resistant coatings using plasma spraying and welding deposition |

| AP-FeCr25Mn13Ni3 | Fe C0.5 Si0.5 Cr25 Mn13 Ni3 | Wear-resistant coatings deposited by plasma spraying. Increased viscosity and wear-resistance for friction with pressure and shocks |

| AP-X5 | Fe base | Hardness of 58-62 HRC. High wear-resistance under shocks and slip velocity and in aggressive environments |

| AP-N10 | Fe base | Hardness of 40-46 HRC. High wear-resistance under heavy loads and slip velocity and in aggressive environments. Resistant to cavitation |

| AP-N4 | Fe base | Hardness of 48-52 HRC. High wear-resistance under heavy loads and slip velocity and in aggressive environments |