語言選擇:

選擇你的語言

In 2018 the factory realized the project “Production of metal high-alloyed powders for weld-deposition, spraying and additive technologies”.

POLEMA’s equipment stock is unique for Russia: an atomizer, sieving and air classifier and a spheroidizing unit are set at the metal powders production site. The up-to-date equipment allowed us to expand the variety of manufactured powders and to enhance their quality.

You can see more information on production process and take a look at the list of powders for 3D printing produced by our company in our presentation.

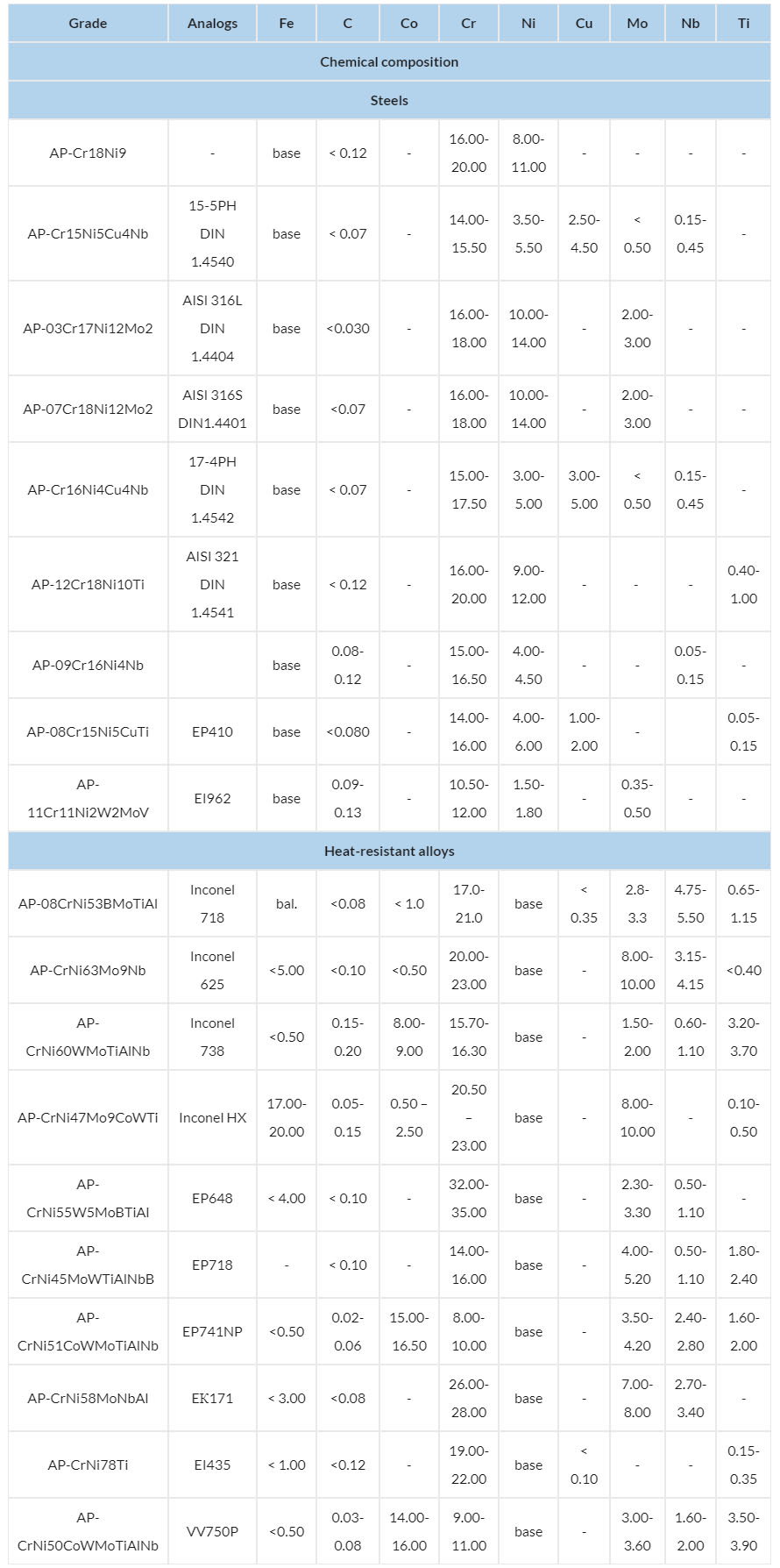

Chemical composition of mass produced powders for 3D printing

| Grade | Analogs | Fe | C | Co | Cr | Ni | Cu | Mo | Nb | Ti |

|---|---|---|---|---|---|---|---|---|---|---|

| Chemical composition | ||||||||||

| Steels | ||||||||||

| AP-Cr18Ni9 | - | base | < 0.12 | - | 16.00-20.00 | 8.00-11.00 | - | - | - | - |

| AP-Cr15Ni5Cu4Nb | 15-5PH DIN 1.4540 |

base | < 0.07 | - | 14.00-15.50 | 3.50-5.50 | 2.50-4.50 | < 0.50 | 0.15-0.45 | - |

| AP-03Cr17Ni12Mo2 | AISI 316L DIN 1.4404 |

base | <0.030 | - | 16.00-18.00 | 10.00-14.00 | - | 2.00-3.00 | - | - |

| AP-07Cr18Ni12Mo2 | AISI 316S DIN1.4401 | base | <0.07 | - | 16.00-18.00 | 10.00-14.00 | - | 2.00-3.00 | - | - |

| AP-Cr16Ni4Cu4Nb | 17-4PH DIN 1.4542 |

base | < 0.07 | - | 15.00-17.50 | 3.00-5.00 | 3.00-5.00 | < 0.50 | 0.15-0.45 | - |

| AP-12Cr18Ni10Ti | AISI 321 DIN 1.4541 |

base | < 0.12 | - | 16.00-20.00 | 9.00-12.00 | - | - | - | 0.40-1.00 |

| AP-09Cr16Ni4Nb | base | 0.08-0.12 | - | 15.00-16.50 | 4.00-4.50 | - | - | 0.05-0.15 | - | |

| AP-08Cr15Ni5CuTi | EP410 | base | <0.080 | - | 14.00-16.00 | 4.00-6.00 | 1.00-2.00 | - | 0.05-0.15 | |

| AP-11Cr11Ni2W2MoV | EI962 | base | 0.09-0.13 | - | 10.50-12.00 | 1.50-1.80 | - | 0.35-0.50 | - | - |

| Heat-resistant alloys | ||||||||||

| AP-08CrNi53BMoTiAl | Inconel 718 | bal. | <0.08 | < 1.0 | 17.0-21.0 | base | < 0.35 | 2.8-3.3 | 4.75-5.50 | 0.65-1.15 |

| AP-CrNi63Mo9Nb | Inconel 625 | <5.00 | <0.10 | <0.50 | 20.00-23.00 | base | - | 8.00-10.00 | 3.15-4.15 | <0.40 |

| AP-CrNi60WMoTiAlNb | Inconel 738 | <0.50 | 0.15-0.20 | 8.00-9.00 | 15.70-16.30 | base | - | 1.50-2.00 | 0.60-1.10 | 3.20-3.70 |

| AP-CrNi47Mo9CoWTi | Inconel HX | 17.00-20.00 | 0.05-0.15 | 0.50 – 2.50 | 20.50 – 23.00 | base | - | 8.00-10.00 | - | 0.10- 0.50 |

| AP-CrNi55W5MoBTiAl | EP648 | < 4.00 | < 0.10 | - | 32.00-35.00 | base | - | 2.30-3.30 | 0.50-1.10 | - |

| AP-CrNi45MoWTiAlNbB | EP718 | - | < 0.10 | - | 14.00-16.00 | base | - | 4.00-5.20 | 0.50-1.10 | 1.80-2.40 |

| AP-CrNi51CoWMoTiAlNb | EP741NP | <0.50 | 0.02-0.06 | 15.00-16.50 | 8.00-10.00 | base | - | 3.50-4.20 | 2.40-2.80 | 1.60-2.00 |

| AP-CrNi58MoNbAl | EК171 | < 3.00 | <0.08 | - | 26.00-28.00 | base | - | 7.00-8.00 | 2.70-3.40 | - |

| AP-CrNi78Ti | EI435 | < 1.00 | <0.12 | - | 19.00-22.00 | base | < 0.10 | - | - | 0.15-0.35 |

| AP-CrNi50CoWMoTiAlNb | VV750P | <0.50 | 0.03-0.08 | 14.00-16.00 | 9.00-11.00 | base | - | 3.00-3.60 | 1.60-2.00 | 3.50-3.90 |

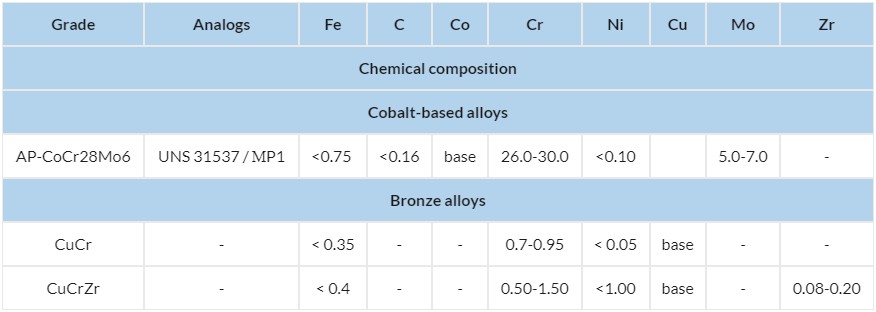

| Grade | Analogs | Fe | C | Co | Cr | Ni | Cu | Mo | Zr |

|---|---|---|---|---|---|---|---|---|---|

| Chemical composition | |||||||||

| Cobalt-based alloys | |||||||||

| AP-CoCr28Mo6 | UNS 31537 / МP1 | <0.75 | <0.16 | base | 26.0-30.0 | <0.10 | 5.0-7.0 | - | |

| Bronze alloys | |||||||||

| CuCr | - | < 0.35 | - | - | 0.7-0.95 | < 0.05 | base | - | - |

| CuCrZr | - | < 0.4 | - | - | 0.50-1.50 | <1.00 | base | - | 0.08-0.20 |