語言選擇:

選擇你的語言

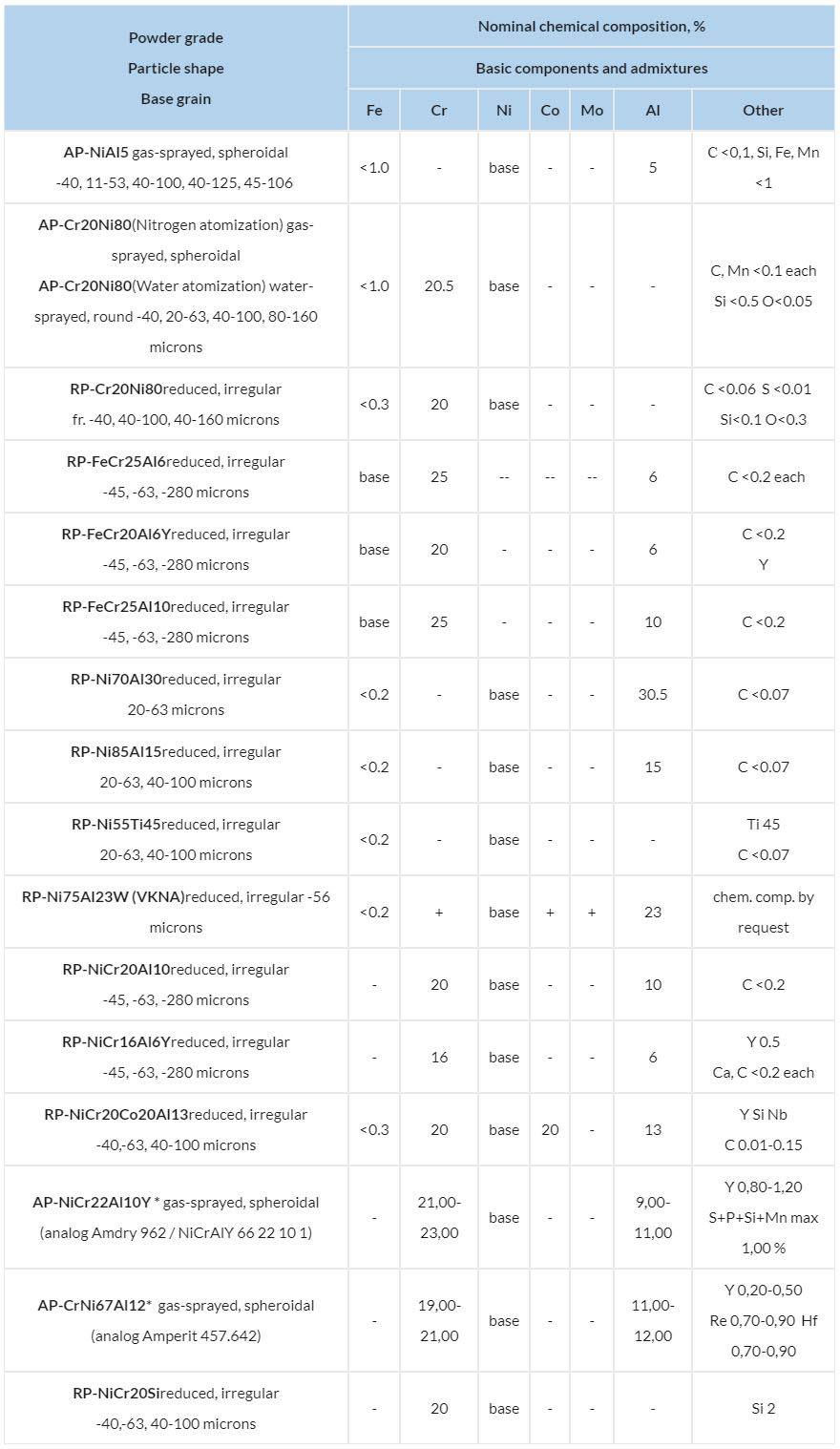

| Powder grade Particle shape Base grain |

Nominal chemical composition, % | ||||||

|---|---|---|---|---|---|---|---|

| Basic components and admixtures | |||||||

| Fe | Cr | Ni | Co | Mo | Al | Other | |

|

AP-NiAl5 gas-sprayed, spheroidal -40, 11-53, 40-100, 40-125, 45-106 |

<1.0 | - | base | - | - | 5 | С <0,1, Si, Fe, Mn <1 |

|

AP-Cr20Ni80(Nitrogen atomization) gas-sprayed, spheroidal AP-Cr20Ni80(Water atomization) water-sprayed, round -40, 20-63, 40-100, 80-160 microns |

<1.0 | 20.5 | base | - | - | - | C, Mn <0.1 each Si <0.5 O<0.05 |

|

RP-Cr20Ni80reduced, irregular fr. -40, 40-100, 40-160 microns |

<0.3 | 20 | base | - | - | - | C <0.06 S <0.01 Si<0.1 O<0.3 |

|

RP-FeCr25Al6reduced, irregular -45, -63, -280 microns |

base | 25 | -- | -- | -- | 6 | C <0.2 each |

|

RP-FeCr20Al6Yreduced, irregular -45, -63, -280 microns |

base | 20 | - | - | - | 6 | C <0.2 Y |

|

RP-FeCr25Al10reduced, irregular -45, -63, -280 microns |

base | 25 | - | - | - | 10 | C <0.2 |

|

RP-Ni70Al30reduced, irregular 20-63 microns |

<0.2 | - | base | - | - | 30.5 | C <0.07 |

|

RP-Ni85Al15reduced, irregular 20-63, 40-100 microns |

<0.2 | - | base | - | - | 15 | C <0.07 |

|

RP-Ni55Ti45reduced, irregular 20-63, 40-100 microns |

<0.2 | - | base | - | - | - | Ti 45 C <0.07 |

| RP-Ni75Al23W (VKNA)reduced, irregular -56 microns | <0.2 | + | base | + | + | 23 | chem. comp. by request |

|

RP-NiCr20Al10reduced, irregular -45, -63, -280 microns |

- | 20 | base | - | - | 10 | C <0.2 |

|

RP-NiCr16Al6Yreduced, irregular -45, -63, -280 microns |

- | 16 | base | - | - | 6 | Y 0.5 Ca, C <0.2 each |

|

RP-NiCr20Co20Al13reduced, irregular -40,-63, 40-100 microns |

<0.3 | 20 | base | 20 | - | 13 | Y Si Nb C 0.01-0.15 |

|

AP-NiCr22Al10Y * gas-sprayed, spheroidal (analog Amdry 962 / NiCrAlY 66 22 10 1) |

- | 21,00-23,00 | base | - | - | 9,00-11,00 | Y 0,80-1,20 S+P+Si+Mn max 1,00 % |

|

AP-CrNi67Al12* gas-sprayed, spheroidal (analog Amperit 457.642) |

- | 19,00-21,00 | base | - | - | 11,00-12,00 | Y 0,20-0,50 Re 0,70-0,90 Hf 0,70-0,90 |

|

RP-NiCr20Sireduced, irregular -40,-63, 40-100 microns |

- | 20 | base | - | - | - | Si 2 |

*New materials: Ni-Cr-Al-Y system alloys for coatings application in aerospace industry.

Alloys of the Ni-Cr-Al-Y system are most widely used to obtain coatings on blades operating at high temperatures and thermal stresses.

Sprayed powders may be delivered with other particle size not presented in the table, in microns: 45-125, -125, 100-140, 100-280, 160-280, 280-400.

Properties of NiAl metallides

Erosion-resistant alloyed powders AP-FeCr17Ni8Si6Mn (ZN-6L) and AP-FeCr18Ni9Mo5Si5Mn4Nb (ZN-12M) were developed for high-performance and high-quality plasma-jet hard-facing of wear-resistant coatings onto sealing surfaces of power equipment valving parts in lieu of the coating electrodes well-known in the valving industry. Powder grades designation in brackets are the grades of coating electrodes according to GOST 100The basic phase in the material RP-Ni70Al30 is the metallide NiAl (β` - phase >95%), while in RP-Ni85Al15 it is the metallide Ni3Al (γ`- phase >95%), and in VKNA the metallide Ni3Al (γ`- phase). The materials' structure in a coating is marked by high resistance to recrystallization during use at high temperatures.

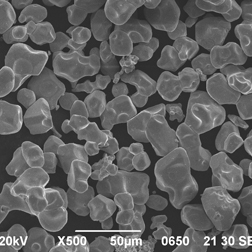

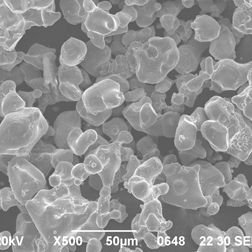

Particle shape

RP-Ni85Al15

VKNA

Particle size

Base fraction 20-63 microns, VKNA powder 56 microns.

The typical average size (conditional diameter) of powder particles is 30-40 microns

Physical-mechanical properties of powders and coatings

VKNA is a heat-resistant super-alloy based on the metallide Ni3Al, phase-strengthened with admixtures of infusible metals, which is characterized by outstanding physical and mechanical properties of plasma coatings: structural thermal stability, heat-resistance and wear-resistance when used as parts in gas-turbine engines at temperatures of 1150-1200 0C.

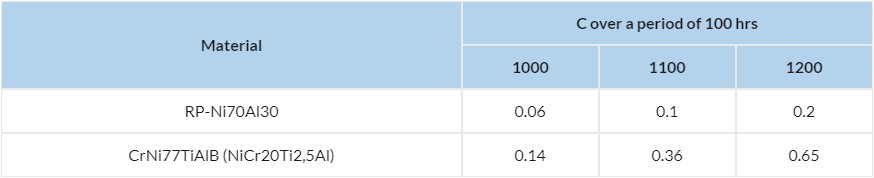

RP-Ni70Al30 Smelting temperature 1640 0C. Exclusively high heat-resistance when heated in open air, more than three times greater resistance to corrosion than the common heat-resistant alloy CrNi77TiAlB.

| Material | C over a period of 100 hrs | ||

|---|---|---|---|

| 1000 | 1100 | 1200 | |

| RP-Ni70Al30 | 0.06 | 0.1 | 0.2 |

| CrNi77TiAlB (NiCr20Ti2,5Al) | 0.14 | 0.36 | 0.65 |

RP-Ni70Al30 in plasma coatings is corrosion-resistant in the atmosphere, water and in alkalis (NaOH and KOH solutions).

Surface hardness is approximately 40 HRC; the material forms durable coatings with steel and copper and is well pressed and sintered in a vacuum.

RP-Ni85Al15 Melting point is 1400 0C; excellent heat-resistance of coatings when heated in open air to 1150 0C; the material and coatings are durable in the atmosphere, water and alkalis.

Hardness of plasma coatings is approximately 300 HB; the material forms durable coatings with steel and copper.